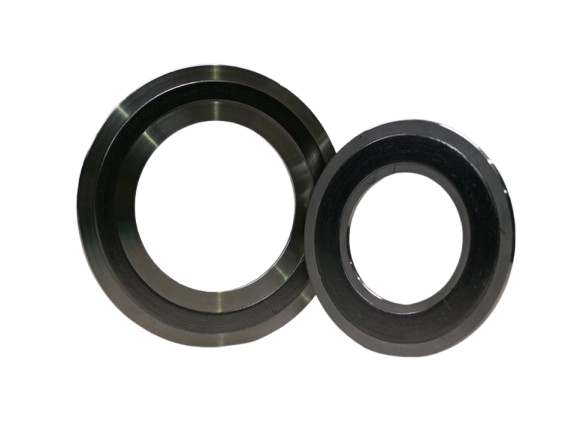

Spiral Wound

Gasket

At Metrade, we provide high-performance spiral wound gaskets that are designed to meet the rigorous demands of the water industry. Our gaskets are engineered for reliability, durability, and long-term performance, ensuring that your water systems remain leak-free and efficient. Our team is available to help you choose the right gasket for your system, ensuring optimal performance and safety. We offer fast and reliable shipping to ensure your project stays on schedule.

Spiral wound gaskets are a type of sealing component used in flanged connections to prevent leakage of liquids or gases under pressure. These gaskets are made by winding multiple layers of a metal strip and a filler material, which creates a spiral design. The outer metal layers provide strength and resilience, while the filler material ensures a proper seal under varying pressures and temperatures.

In the water industry, spiral wound gaskets are commonly used in high-pressure pipelines, water treatment plants, and other critical water systems where leak prevention and system integrity are paramount. They are designed to form a reliable, tight seal, even under high-pressure conditions. Their structure allows them to compress and adapt to the mating surfaces of flanged connections, providing an effective barrier against leakage. The metal strips in spiral wound gaskets provide excellent resistance to thermal expansion and contraction, while the filler material accommodates temperature changes. These gaskets maintain their integrity in both high- and low-temperature environments, making them ideal for water systems subject to fluctuating temperatures or extreme conditions.

It consists of multiple elements that work together to provide reliable and durable sealing performance. They are: