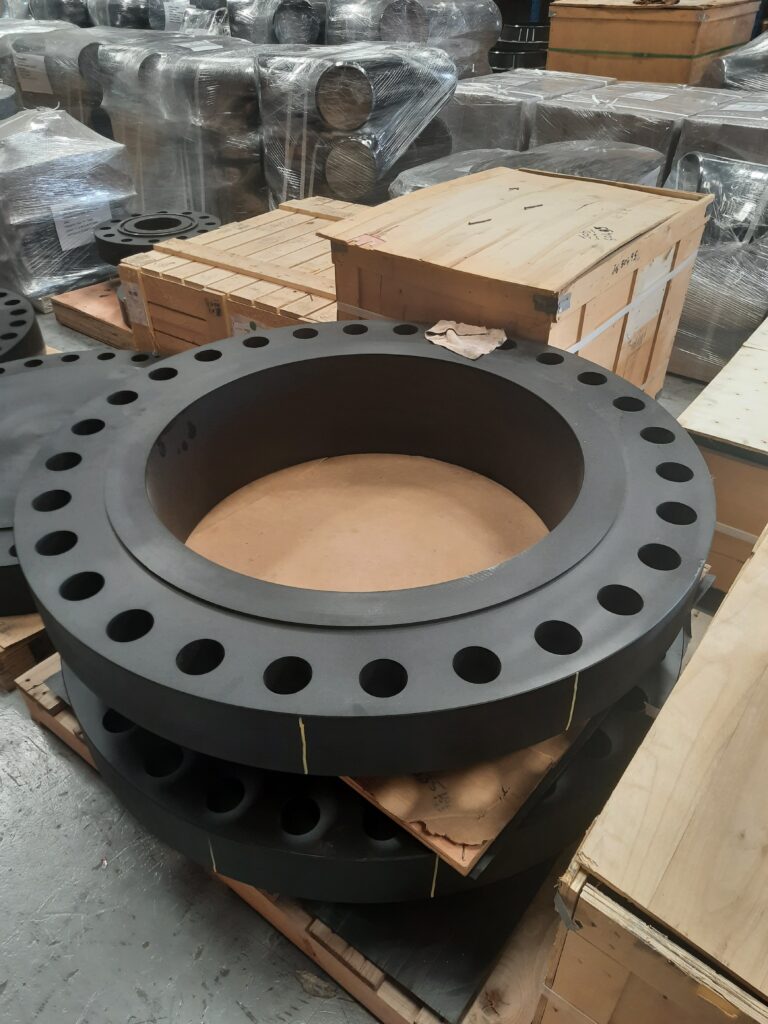

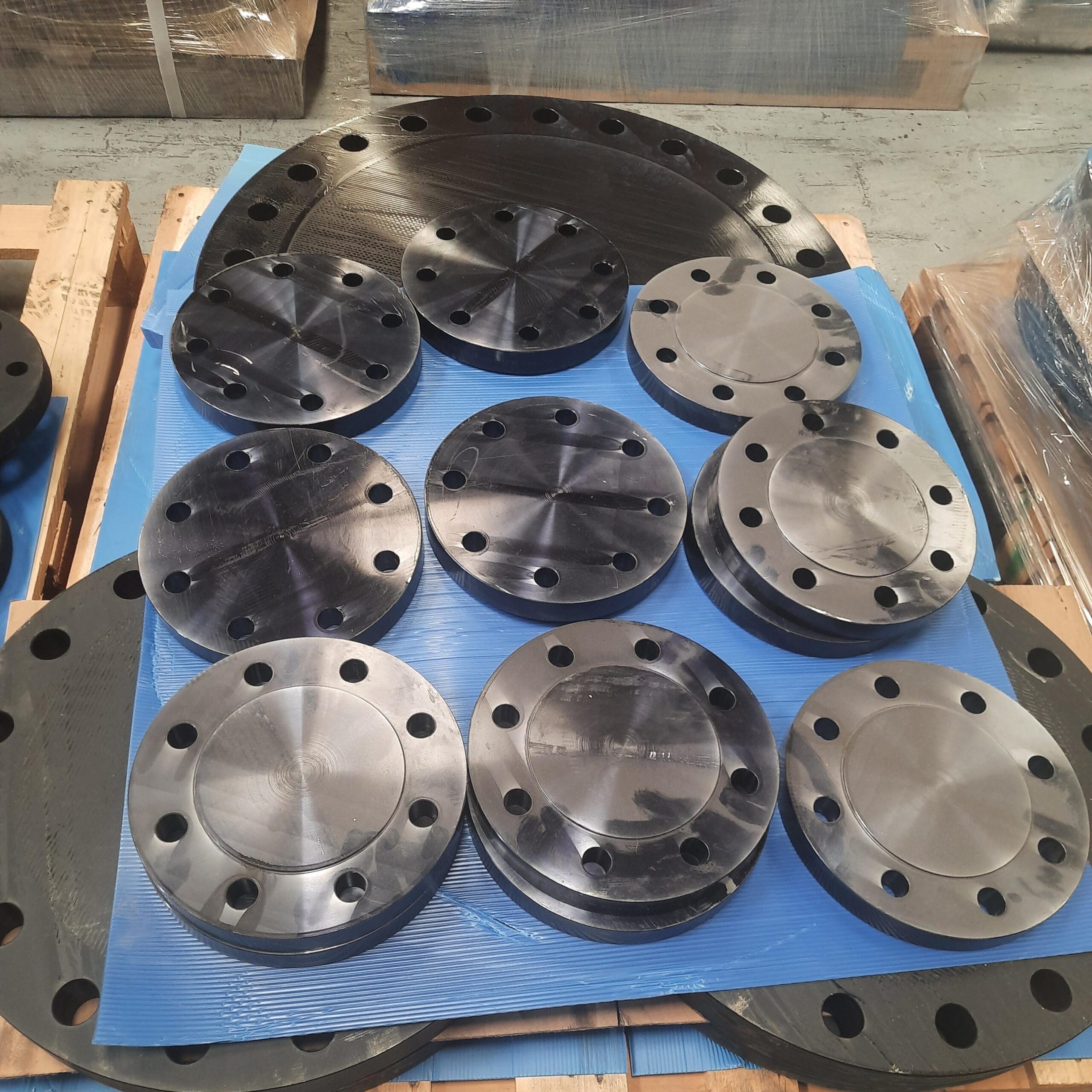

FLANGES

Strength and Reliability in Every Flange Connection

At Metrade, we offer a comprehensive range of flanges designed to provide secure, leak-proof connections in your piping systems. Whether you’re working in construction, oil and gas, water treatment, or any other industry that requires durable, high-performance flow control, our flanges offer unmatched strength, reliability, and versatility. With a variety of materials, sizes, and pressure ratings available, our flanges are engineered to meet the most demanding requirements.

A flange is a mechanical component used to connect pipes, valves, pumps, or other equipment in a piping system. Flanges provide a tight seal by joining two parts with bolts, washers, and gaskets. They are designed to withstand high pressures, temperatures, and harsh environments, ensuring a long-lasting and leak-proof connection in critical systems. Flanges are commonly used in a variety of industries, including oil and gas, chemical processing, power generation, and water treatment, to ensure safe, efficient, and leak-free flow control.

The principle of a flange is to use a mechanical force by using bolts to preload the gasket until there is enough contact stress between the flanges and the gasket to maintain a seal. The connection to pipe is done by welding or threaded connections. Flanges can also provide easy access for cleaning, inspection or modification and pipes with flanges can be assembled and disassembled easily. Flanges tend to be either welded or screwed into place.

Material | Specification | Grades |

|---|---|---|

| Carbon Steel | ASTM A105 | A105 |

| Low Temperature Carbon Steel | ASTM A350 | LF2 and LF3 |

| Stainless Steel and Special Stainless Steel | ASTM A182 | F304/304L, 316/316L, 310, 317, 321, 347, 410, 904, H |

| Alloy Steel | ASTM A182 | F5 / 9 / 11 / 22 / 91 |

| Nickel Alloy 200/201 | B564 | UNS N02200/N02201 |

| Nickel Alloy 276 | B564 | UNS N10276 – Hastelloy C-276 |

| Nickel Alloy 400 | B564 | UNS N04400 – Monel 400 |

| Nickel Alloy 600 | B564 | UNS N06600 – Inconel 600 |

| Nickel Alloy 625 | B564 | UNS N06625 – Inconel 625 |

| Nickel Alloy 800H/800HT | B564 | UNS N08810/N08811 – Incoloy 800H/HT |

| Nickel Alloy 825 | B564 | UNS N08825 – Incoloy 825 |

| Titanium Alloy | B381 | Gr 1 / 2 / 5 / 7 |